Stainless Steel Handles

Stainless steel handles are widely used in a different industrial case. At Rochehandle, you can buy stainless steel handles of various designs, for example, U shape, bridge shape, foldable and many others.

What comes into your mind when you hear of stainless steel handle? The most probable answer is strong, durable, and versatile pull handles. These are just some of the reasons why you should stick to stainless steel pull handles if you need quality assurance.

These handles are made of 100% stainless steel which is everyone’s favorite metal for handles. Most people tend to have soft spots for stainless steel door handles, stainless steel chest handles, stainless steel cupboard handles, stainless steel industrial handles, stainless steel spring handles, and stainless steel cabinet handle types. This is mainly because of the desirable features of these steel materials.

Apart from being durable, it is easy to maintain stainless steel handles. Cleaning these stainless steel furniture handles won’t be a difficult task as compared to other materials. Also, you don’t need to add many sophisticated finishes to make stainless steel attractive. However, with Rochehandle in play, you will enjoy several stainless steel coating options.

Stainless steel handles are quite versatile. They are available in different shapes and designs. Yours is to choose the design that will match with the interior of the room. You can even ask for customized stainless steel door handles from Rochehandle.

Are you planning to buy stainless steel handles? It is important to you buy from the best stainless steel handle suppliers in China. We at Rochehandle focus on manufacturing and supplying premium-quality new steel handles to our customers.

CEO Notes

Hey! This is Robin, Roche Industrial Co.,Ltd Product CEO. Thanks to visit our website,and I hope to be a friend with you here. I have over 10 years experience in Handles,I would like to share my experience in this field,and any questions you have about handles ,I'm happy to help you. I provide free consultant for many clients,and if you need any help on handles,reach me any time with below button.

Helpful Resources To Know More About Handles

Things You Need to Know About Stainless Steel Handles & Surface Treatment

Stainless Steel Handles & Surface Treatment

With the high demand for handles these days, there are a growing number of options available over the market. That’s the reason why deciding how to choose the best handle will be more difficult than expected. The available materials for handles are aluminum, brass, copper, chrome, iron, nickel, crystal, marble, zinc, glass, pewter, stone, and wood. Considering this, choosing the one that suits your needs will be quite overwhelming.

All materials integrated and used in manufacturing handles are remarkable. For example, for a handle with a high manifestation of brass, it has a superior tarnish resistance. But if it does not have a good content of the metal, it can easily show corrosion in no time.

When it comes to copper handles, it is known to fight corrosion and other issues. However, similar to brass, it corrodes over time. Despite this, it’s still a good choice as it plays a vital role in fighting impurities such as Clostridium difficile and MRSA. Experts have proven that it can fight pathogens. Within a few hours, the bacteria will vanish on copper surfaces.

On the other hand, a chrome handle has an attractive shiny finish. Whether you will use it for your cabinetry or other furniture, a chrome handle can transform it into a more stunning and appealing one. It feels sleek and firm, giving you optimal convenience. You will never have a hard time opening or closing your drawer, wardrobe, door, etc. Besides, it can be maintained without an extensive process. Cleaning is very simple too. All you need is a wet cloth and simply wipe it.

Every material for a modern handle is no doubt beneficial for its purpose. But all of these have downsides too. The good thing here is that there are other materials to take into account. One of those is stainless steel. Just like the others, it has been known for its corrosion-resistance property. For people whose existing handle corrodes, this material will be a perfect option.

Stainless steel also has a high cryogenic toughness, work hardening rate, hot strength, ductility, hardness, and strength. Aside from being sturdy, it has a more attractive appearance compared to other materials mentioned above. Plus, it does not require extensive maintenance. You can maintain its functionality and appeal. There is no need to ask help from a professional service provider.

There is no doubt that stainless steel is an impressive material for everyone. If you want to learn more, just keep reading. This guide will tell you everything you need to know about stainless steel handles.

Chapter 1: Different Grades In Stainless Steel For An Easy Selection

Nowadays, there is a wide array of stainless steel found in the market. Each has its unique qualities and composition. Depending on the chemical composition, stainless steel may be harder, easier to work with, stronger, and magnetic. Following is the short list of different grades of stainless steel.

- 201 Stainless Steel Handles

What is type 201 stainless steel?

201 stainless steel is an alloy consist of nickel, manganese, and nitrogen. While it is less costly than others, it is not simple to form. It is an authentic metal, which makes this type of stainless steel non-magnetic. It contains a high level of chromium and nickel. 201 stainless steel is also known to have low levels of carbon.

Other facts about handles made from type 201 stainless steel

Type 201 stainless steel is considered as a mid-range product with an array of useful qualities. While it is perfect for particular uses, it is not an ideal option for structures that are prone to any corrosive forces, including salt water.

Here are the other things to know about this grade:

- Type 201 belongs to the 200 series of stainless steels. It is originally developed to conserve nickel. Low content of nickel characterizes it.

- Type 201 is a good alternative for 301 in some applications. Nevertheless, it is less corrosion-resistant than its counterpart.

- This grade of stainless steel is non-magnetic. But it can become magnetic thru cold working. The higher nitrogen content in type 201 offers higher toughness and yield strength than 301 steel. However, this will only take place at low temperatures.

- Heat treatment does not harden it. It is annealed at 1850-1950 degrees Fahrenheit. Then, it is followed by rapid air cooling and water quenching.

- It is also utilized to produce many different household appliances. Aside from sinks, washing machines, doors, windows, and cooking utensils, it is used in modern handles for furniture. It is also utilized in automotive trim, railway cars, clamps, trailers, decorative architecture, and a lot more. But it is not recommended for any outdoor structural applications as it is susceptible to crevice and pitting corrosion.

- Handles made of grade 201 stainless steel is generally lower in cost. It’s because it consists of different mechanical properties. Its corrosion resistance is a bit similar to grade 304. Apart from handles, it tends to be used in catering equipment and kitchen utensils.

- 304 Stainless Steel Handles

Modern handles that are listed as 304-grade stainless steel contain the following characteristics:

304 stainless steel handles are made from low carbon steel that has a chromium alloy. It contains at least 15% chromium and 10% nickel. The presence of chromium alloy gives the accessories a unique and strong corrosion resistant properties.

Generally speaking, stainless steels are resistant to rust. But they are not immune to it. They will corrode over a long period. Thus, regular or holistic cleaning is necessary to help prevent the growth of corrosion. It is also a great way to extend the life of modern handles.

Stainless steel offers a clean and stunning finish with low maintenance expenses. 304 stainless steel is the most common grade of stainless steel across the globe. With its excellent value and corrosion resistance, there is no doubt that a lot of homeowners and business establishment proprietors take advantage of it.

Unlike 201 stainless steel, it contains between 16 and 24% of chromium. It also has 35% nickel. Plus, it has a small amount of manganese and carbon. Its most common form is 18-8 or 18/8. More particularly, it is made of 18% chromium and 8% nickel.

Another good thing about 304 stainless steel is that it can withstand corrosion from oxidizing acids. For that reason, 304 stainless steel handles are easy to sanitize. That makes them perfect for kitchen applications. At present, they are commonly used in décor, buildings, and site furnishings.

304 stainless sheets of steel have a downside too. It is susceptible to corrosion from any chloride solutions or saline environments. Chloride ions can create corrosion, also called as pitting. It can spread beneath chromium barriers, affecting internal structures.

- 316 Stainless Steel Handles

The second-most common form of stainless steel is 316 stainless steel. 316 has the same mechanical and physical properties to 304 stainless steel. In fact, it is made of similar material makeup, but both still have differences. The 316 stainless steel incorporates 2 or 3% molybdenum. It increases the ability of modern handles to fight against corrosion. More particularly, it can withstand industrial solvents such as chlorides.

Aside from being used in modern handles, it is employed on other industrial applications that involve high saline environment and processing chemicals. Because of its non-reactive qualities, it is likewise utilized in the development of production of medical-surgical instruments.

Type 316 stainless sheets of steel utilize nickel to maintain a great and austenitic composition at a lower temperature. Austenitic steels guarantee a flexible balance of strength, corrosion resistance, and workability. That is why they are also an ideal option for landscape and outdoor architectural applications as well.

316 modern stainless handles are also popular for having good weldability, excellent ductility, ease of manufacture, and work hardening for spring properties. They are also hygienic, making your cabinetry or other furniture comfortable and pleasant.

Another grade for stainless steel modern handles

- 430 Stainless Steel Handles

Grade 430 stainless steel modern handles are resistant to rust. However, they are not as good as 304 and 316. They are hygienic, making your pulls clean at all times. They are cost-effective, giving you the chance to get more savings. They are magnetic and suitable for indoor use. Unlike other grades, they can come in to contact with detergents, cleaning fluids, and other mild chemicals.

Apart from handles, 403 stainless sheets of steel are applied in washing machine drums, extraction units, cooker hobs, catering equipment, hinges, and a lot more.

Here at Rochehandle, all our products are made from the highest quality stainless steel. We are proud to provide items that are suitable for countless applications. For more information, feel free to give us a call. Our customer representatives are always ready and dedicated to help and serve you!

Chapter 2: Common Applications Of Stainless Steel Handles

Due to the durability and functionality of stainless steel handles, they are used in different applications. Mostly, they are used in different industry equipment like medical equipment, food equipment, equipment controls, industrial equipment, automotive, HVAC, outdoor power equipment, farm, and construction machinery.

Stainless steel handles are also used in furniture and appliances. Take a closer look at the following:

- Stainless steel for cabinet handles

Cabinets play a vital role in increasing personalization of your home. They will complement the unique and special appeal of the living space. They also have a longer shelf life, eliminating unnecessary expenses. But without a durable and aesthetic stainless steel handle, you cannot get the most out of your cabinet. Stainless steel cabinet handles are an excellent solution you can ever have. They are an amazing investment, making you happy in the long run.

- Stainless steel handles for refrigerator

It is said that stainless steel handles are applied in appliances like the refrigerator. Stainless steel handles for refrigerator are long-lasting. They can withstand the commotion of a busy home. During accidental collisions, these won’t easily scratch. Despite constant and messy use, they will resist rust and stain for your convenience.

- Stainless steel handles for BBQ grills

Aside from appliances, stainless steel handles are used in other cooking equipment such as BBQ grills. They are easy to clean. In fact, cleanup will be a breeze. You can wipe up spills thru a clean rag. You can likewise use soap and water to keep it tidy and sparkling. There are also other polishes that can remove stubborn messes and repel dirt on the surface.

- Stainless steel bathroom handles

One of the dirty living spaces at home is the bathroom. So, it is important to keep it clean. But how? Using stainless steel bathroom handles will be a great help. Even though it only offers little improvement, it’s still helpful. Stainless steel bathroom handles are non-porous, resisting germs and bacteria. These are great for homes with kids and animals. But it does not necessarily mean that you will not use a cleaner. Utilize a disinfectant solution to sanitize the area and provide a safe bathroom for everyone.

- Stainless steel cupboard handles

Stainless steel handles are also found in the cupboard because of their neutral look. They can complement the personality of kitchen or home as a whole. Whether your space is full of natural wood cupboards, marble countertops, or stainless steel appliances, they can blend seamlessly. They can transform the atmosphere into an exciting and light environment.

- Stainless steel door handles

Stainless steel handles can also be found attached to doors. Over the past few years, we have seen how door hardware has evolved. Before, people used wood and simple doorknobs. Around 1910, the glass doorknob has come out in the market. The design was more stylish and decorative. At the latter part of the 19th century, metal door knobs have emerged for the locking mechanism.

And today, stainless steel door handles are available. They are strong and can withstand the test of time. They are resistant too. The majority of products out there have chromium finish, making them more suitable in an environment prone to moisture. That is why they are a perfect door accessory.

- Stainless steel drawer handles

Stainless steel has also been integrated into drawers. Like other applications, they have an attractive or nickeled look. Because of the designs, they are the most sought-after options for many homeowners. Moreover, they have rust resistant properties.

- Stainless steel oven handles

Lastly, stainless steel handles are used in ovens. They have a beautiful or modern appearance that isn’t found in other materials. They can withstand years of use without signs of damage or wear. They are resistant to water damage and rust too. Plus, they will fit surely to your kitchen theme.

Chapter 3: Shapes Of Stainless Steel Handles For Your Furniture And Appliances

- Bow handles

Bow handles are similar to objects you commonly see in archery. They are convenient to use and easy to grip. You will never encounter trouble opening or close your furniture. They are available in different finishes and style to help you find your best option. You can search online to find different options that suit your needs.

- Crank handles

Stainless steel crank handles are commonly used in different applications where leverage from an arm unit is best. Here at Rochehandle, we have crank handles for an array of industrial product. All of our solutions are engineered and manufactured in a way that exceeds the strict industry standards.

Aside from stainless steel, we incorporate other materials in manufacturing crank handles. We have plastic and aluminum. Many of our products are available in several color options and styles.

- Chest Handles

When looking for a unique pull, stainless steel chest handles come to your rescue. They are precisely designed and durable. They also have a vibrant design and compactness, making them an awesome investment.

Rochehandle have gained a remarkable position in the industry by providing stainless steel chest handles. Our team of productive and versatile professionals puts their efforts into manufacturing our products. We utilize topnotch raw material and modish technology.

For us to deliver defect-free handle, we test our products on various quality parameters. Moreover, our valuable clients can avail our products in several patterns and sizes at a reasonable cost.

- Recessed Handles

Every door, cupboard, window, fence, or cabinet needs a handle to be operated. Handles are normal, which have been in the industry for centuries. However, having a new house and installing new doors aren’t only about the utility of options. You have to pay attention to the aesthetic value of your choice. It is where stainless steel recessed handles come in.

Recessed handles allow you to enjoy the benefits of a door handle. You can open, close or operate it without hassle. When looking for a smooth and seamless profile, recessed handles are your best bet. They are not weaker than their other counterparts. By installing them in your door, cupboard, or drawer, the risk of ineffective protection and premature breakage can be avoided. Here at Rochehandle, our stainless steel recessed handles are of good quality, with production value, and longevity of use.

Serving our valuable clients over the years, we have a team of flexible engineers who possess a dedication to offering the best designs. We also have innovative manufacturing facilities that use the most effective production methods and the best materials. In case you experience issues, our customer service team is always ready and willing to be of help! Each of our staff knows our product line very well including their specifications. Our people are passionate and eager to give you a hand whatever the problem you might encounter related to your handle needs.

- Flush Handles

Rochehandle’s line of flush handles provides a clean appearance for your unique designs. Our products are 100% stainless steel, yielding durability. The stylish and stunning features of our handles have corrosion protection as well. Unlike our competitors in the market, we have a rich collection of flush handles. We have multiple styles for you to choose from. Plus, our solutions are non-corrosive for any grade applications.

- Folding Handles

Rochehandle is a certified manufacturer and distributor of folding handles. We are a one-stop source for custom and standard stainless steel handles for everyone.

We carry a large inventory of different styles of folding handles for fast delivery. We provide a quick turnaround quote on diverse requirements. If you are not satisfied with your existing handles, please feel free to contact us. Our products are excellent and available at a competitive price.

- Wire Handles

A wire is present in untreated brass. It is likewise available in a chrome or lacquered finish. Over a long span of time, stainless wire handles will have a beautiful patina. Here at Rochehandle, our wire handles tell about our craftsmanship. Our craftsmen possess the knowledge and experience that will reach your expectations. Rest assured that we can offer responsive and relevant products that you and your family will love.

- Spring Handles

For a flexible option, stainless steel spring handles are manufactured for you. These are stress-free to use. You can hold it without a burden. They are sturdy enough that can last a lifetime. They are also one of the topnotch choices among homeowners because of their catchy design. Moreover, they are stylish, creative, and beautiful that you should consider. So what are you waiting for? Include spring handles into your shopping list today!

Chapter 4: Surface Treatment Of Stainless Steel Handles

Successfully utilizing stainless steel depends on the grade selected, surface finish, environment, the maintenance specified, and the customer’s expectations. Stainless steel offers robust handles. However, they will present poor performance in hard environment. Luckily, surface finishes can be applied chemically and mechanically.

Understanding how mechanical and chemical treatments will affect the characteristics of the surface will provide the best outcome for each client. Chemical treatment is used to improve corrosion performance and appearance as well.

Stainless steel handles withstand corrosion when they are smooth and clean. Clean means being free of any harmful contaminants. When these left unattended, they can create crevices and corrosion.

The common feature of chemical treatment is that they clean the surface of stainless steel. That may smooth or even roughen the steel surface. It may also leave it unaffected. But this depends on the chosen process. If it is performed accordingly, corrosion resistance will become excellent.

Below are the types of surface treatments:

- Pickling

Mixtures of nitric acid and hydrofluoric are generally the most effective surface treatment nowadays. Acids are available as a paste, a bath, or a gel. Commercially manufactured mixtures consist of 25% nitric acid and 8% hydrofluoric acid. Both of these chemicals etch the material that can dull or roughen the surface.

Care is highly needed with these chemicals because of environmental considerations and occupational health.

- Passivation

Nitric acid is typically used in passivation. The treatment is available as a bath, a paste, or a gel. Formulations have 50% nitric acid. Sometimes, they may contain other oxidizers including sodium dichromate. Nitric acid treatment should be used properly so that it would not affect the aesthetic appearance of stainless steel.

Passivation works best by dissolving carbon steel contamination from the surface of the material. It also becomes effective by dissolving out sulphide inclusions.

- Electropolishing

Sulphuric and phosphoric acids are utilized in conjunction with a current density to clean and smooth the surface of the steel. The process attacks round valleys and peaks on the surface. It also raises the chromium proportion at the surface. It can have a substantial effect on the overall appearance with brightness and luster. When it comes to roughness, it only changes by 30%.

- Decontamination

Decontamination literally means de-poisoning. It is considered as a semi-advanced technique where all impurities are removed without affecting the stainless steel. The same thing goes with heat tinting and natural passive layer. So, it does not affect the surface roughness of the steel.

Also, decontamination does not affect plastic or rubber types. In fact, it makes the process useful in super-critical equipment and medical industry. Most polymers do not like strongly acidic oxidants like nitric acid.

Typically, the method is performed in a solution of a weak acid, including formic acid, oxalic acid, phosphoric acid, nitric acid, and a lot more. The temperature is from 20 to 90 degrees Celsius. In case the impurities are sticky, the time may exceed a few hours.

One problem is iron contamination. Fortunately, steel can get away with decontamination like pickling. Rust is soluble in nitric acid. It easily copes with a hot solution of phosphoric acid and citric acid. On the other hand, metallic iron is more soluble in nitric acid.

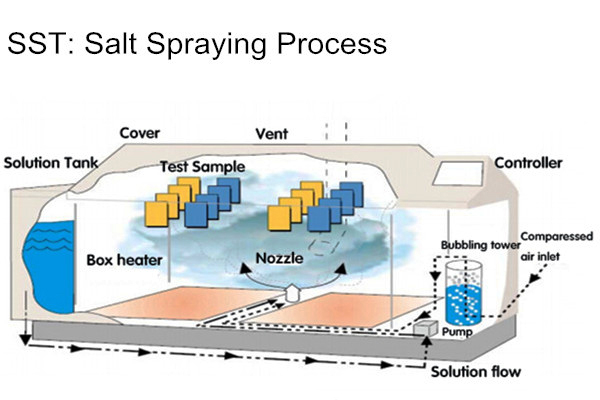

- Salt Spray Test

When the time comes that you need to buy stainless steel handles, you want to ensure that they are of good quality. You depend on their durability and resilience. You like them to hold up even in a harsh environment. Rusted stainless steel handles can be dangerous and expensive to replace. To provide you with the excellent durability, manufacturers rely on salt spray test.

Chapter 5: What Is Salt Spray Test?

Salt spray testing is a technique of checking the corrosion resistance of stainless steel, coatings, and other materials in handles. The coatings are utilized to offer maximum protection for the metal. However, there will be an accelerated corrosive attack during salt spray testing to predict how well the finish protects the metal.

One of the main objectives of the test is to assess the life of the surface coating.

Effectiveness

Stainless steel spray testing is used to produce reliable comparisons between expected and actual corrosion resistance. There is a weak correlation between the surface coating’s duration in the spray test and its expected life in reality. That is because there are external factors that greatly influence corrosion.

Spray test is not a simple process. That usually happens in hot dip galvanized steel because the drying cycles are vital factor to take into account for durability.

For this reason, the method works best when used on samples to identify a pass or fail grade. Whatever the result, it will be then compared to the expectations in an audit role. It is used on zinc, zinc-alloy plating, phosphate surfaces, copper, chromium, paint coatings, electroplated tin, nickel, stainless steel, and a lot more.

Why there’s a need to use it?

Over the years, stainless steel spray test has been the standardized corrosion test technique. Being a quick, inexpensive, and repeatable technique, no wonder why it has been employed as a surface treatment. The first internationally test was dated back to 1939. Today, the ASTMB117 is the most popular salt spray test across the globe. It is also standardized through various certifications like the ISO 9227.

How does it work?

Stainless steel spray test is conducted in a closed and quality testing chamber to ensure treatment accuracy. Strong saltwater is applied to a solution thru a spray nozzle. The salt water fog is utilized to imitate a highly corrosive environment. After a long period, the appearance of oxides is assessed.

The more corrosion resistant a stainless steel handle is, the longer it takes for oxides to come out. The testing duration can last from eight to twenty hours to complete. But this only happens when the material is phosphate steel. For zinc-nickel coatings, it takes place within 720 hours. For zinc flake surface coatings, it will require 1,000 hours.

Types of salt spray testing

A neutral salt spray test with a 5% NaCl solution is used for any steel-based materials. It has a neutral PH level of at least 6.5 or 7.2. When it comes to decorative coatings such as anodized aluminum, electroplated copper nickel chromium, and electroplated copper-nickel are tested with a strong solution of acetic acid with copper chloride (CASS) or acetic acid (ASS). These have a PH from 3.1 to 3.3.

The results of a coating or material’s resistance to corrosion in a spray test can help you determine whether a specific stainless steel handle is resilient, durable, or long-lasting enough for all your needs. It will also let you know how durable and how long it can last and perform its function.

Other amazing uses

Here are the other coatings that can be assessed through the use of salt spray test:

- Phosphate surfaces (These are pre-treated surfaces with subsequent rust, paint, and lacquer.)

- Zinc allow plating

- Electroplated nickel, tin, chromium, and copper

- Coatings that are not applied electrolytically (It includes zinc flake coatings.)

- Organic coatings (i.e., rust preventives)

- Paint coating

Hot dip galvanized surfaces are not evaluated in a salt spray test. When exposed to a harsh environment, it produces zinc carbonates. As a result, it protects the coating metal and eliminates the high rate of corrosion. When a hot dip galvanized sample is exposed to a salt spray fog, there will be no presence of zinc carbonates.

With that, the testing method does not provide a reliable measurement of corrosion protection. For more information about the guidelines about the right measurement of corrosion resistance for hot-dip galvanized surfaces, check out the official website of the ISO 9223.

Conclusion

There you go, you have the list of the things that you need to know about stainless steel handles. When you’ve been searching for the best service provider in the industry for months now, it is time to consider Rochehandle! We manufacture handles that are available in different styles, colors, sizes, and shapes for your comfort. Our rich selection of products will certainly help you make the right decision.

With our decades of experience and in-depth background in the industry, we have the unmatched commitment to offer solutions that align with your requirements. Our people are talented, flexible, and versatile enough to can handle your needs. No matter how high your standard is, we can meet and exceed it. We take pride in how we perform and deal with our business and customers. We do not compromise quality and durability. We love seeing our clients happy and contented with our products and services.

For more information, do not hesitate to give us a call. Or send us a message at handlesupplier@gmail.com. Our pool of professionals is willing to help! Get in touch with us any time of the day. We will respond in the quickest time possible for your convenience, comfort, and satisfaction! Be one of our clients today and see what we’ve got for you!